Home » Manufacturing

Accelerate Your Manufacturing Performance with HPC

High-Performance Computing has emerged as a transformative force, driving efficiency and innovation and supporting manufacturers worldwide to enhance processes and product development.

The Challenges of Traditional Manufacturing Methods

Before diving into the transformative power of HPC, let’s acknowledge the limitations of traditional manufacturing methods:

- Physical Prototyping: Extensive reliance on physical prototypes for testing can be time-consuming and expensive. This limits the ability to iterate on designs quickly, hindering innovation.

- Limited Design Exploration: Traditional design methods may restrict exploring a wider range of design possibilities to optimise performance or reduce costs. This can lead to missed opportunities for creating truly groundbreaking products.

- Data Silos and Inefficiency: Manufacturing data from various sources often remains siloed. This fragmented approach hinders the ability to gain holistic insights and optimise production processes, leading to inefficiencies.

These challenges can translate to longer time-to-market, higher production costs, and ultimately, a loss of competitive advantage.

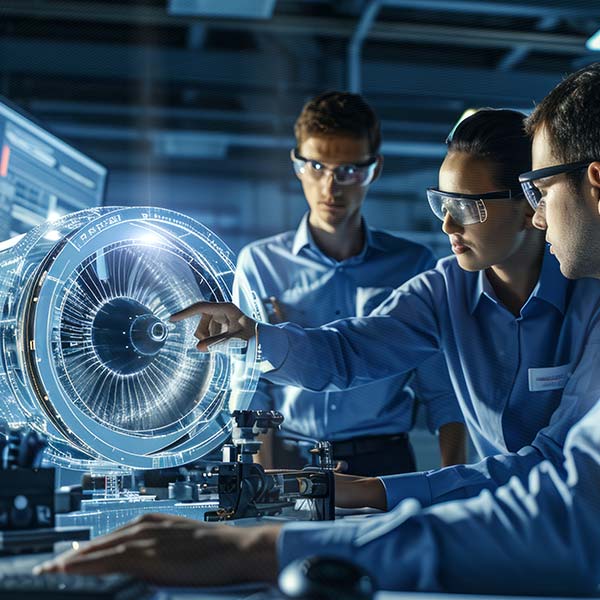

Advanced Simulations

HPC facilitates the creation of high-fidelity simulations of real-world manufacturing processes. Imagine virtually testing the performance of a new product design, simulating production line efficiency under various scenarios, or analysing the stress distribution on a manufactured component.

Design Optimisation

HPC allows manufacturers to leverage powerful optimisation algorithms. Imagine feeding design parameters into an HPC system that can explore countless variations, identifying the optimal design for strength, weight reduction, or energy efficiency.

Big Data Analytics for Manufacturing

Modern manufacturing generates vast amounts of data from sensors, machines, and production lines. HPC empowers manufacturers to analyse this “Big Data” efficiently, uncovering valuable insights to optimise production processes, predict maintenance needs, and improve overall quality control.

Benefits of HPC in Manufacturing:

Reduced

Time-to-Market

Faster simulations and design optimisation cycles powered by HPC accelerate product development. This allows manufacturers to bring innovative products to market quicker, capitalising on emerging trends and consumer demands.

Enhanced Design Optimisation

HPC facilitates the use of powerful optimisation algorithms. Imagine feeding design parameters into an HPC system that can explore countless variations, identifying the optimal design that meets all performance criteria while minimising weight, cost, or energy consumption. This leads to superior product quality and efficiency.

Improved Production Efficiency

HPC-powered simulations allow manufacturers to virtually test production line efficiency under various scenarios. Additionally, Big Data analytics derived from sensor and machine data empowers proactive maintenance, minimising downtime, and optimising resource allocation.

Data-Driven

Decision Making

HPC unlocks the power of Big Data. By analysing vast amounts of data from across the manufacturing ecosystem, manufacturers gain valuable insights. This empowers informed decision-making, from resource allocation to production planning, ultimately driving overall business success.

Why Red Oak Consulting?

Implementing a successful HPC solution requires expertise and a deep understanding of your specific manufacturing needs. With a proven track record of partnering with manufacturers across diverse industries, here’s what sets us apart:

- Needs Assessment: We collaborate closely with you to understand your manufacturing challenges and identify areas where HPC can deliver the most significant impact.

- Custom HPC Solution Design & Implementation: Our experts design and implement a customised HPC solution tailored to your specific production processes and budget.

- Workflow Optimisation: We help optimise your workflows to leverage HPC effectively, ensuring you maximise the benefits for your manufacturing environment.

- Unparalleled Expertise: Our team of HPC specialists possesses in-depth knowledge of both HPC technology and the unique challenges faced by manufacturers.

- Custom-Tailored Solutions: We don't offer a one-size-fits-all approach. We work closely with you to understand your specific needs and design an HPC solution that seamlessly integrates with your existing infrastructure and workflows.

- Maximised ROI: We focus on maximising your return on investment. Our solutions are designed for scalability and future-proofing, ensuring they continue to deliver value as your needs evolve.

Explore Our Range of HPC Consultancy Services

Strategy & Planning

Develop an HPC strategy that meets the current and future

needs of all users and includes securing funding for a sustainable solution.

Procurement

Managing the complex process of HPC technical specifications, as in-depth as required, to deliver the right solution, on time and in budget.

Implementation

Reduce downtime, mitigate risk, improve performance and ensure reliability to enhance business productivity.

Expansion & Optimisation

Understand your workflows, the ratio of computational intensity vs data intensity, test performance, speed, agility, whilst analysing all HPC costs to understand its true value.

Maintenance & Support

Boost productivity with our HPC Cloud Computing services, including expert support, system management and research engineering.

Cloud Consultancy

Understand the value of Cloud computing for both businesses and users through enhanced capability, workload optimisation, and increased productivity.

Related Resources

Tips for Cloud HPC Clusters

Deployment and Management from the front line Infrastructure-as-Code Infrastructure-as-code is an inherent advantage of using the cloud. Simply put, this…

Federal Investment in Exascale – What It Really Means

Perspective — Earlier this month, the EuroHPC JU (Joint Undertaking) reached critical mass, and it seems all EU and affiliated member states, bar the UK (unsurprisingly), have or will sign on.

Debunking HPC Myths

Using our proven track record and experience as independent HPC consultants, we have debunked a few of the most common HPC myths out there.